- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Umatshini wokugcwalisa

- Izixhobo ezixhasayo ekugcwaliseni umgca weMveliso

- Inkqubo yokuHambisa izinto eziphathekayo

- Umatshini wokuzalisa ulwelo lweMichiza

- Umatshini wokuzalisa iiBhakethi eziNcinci zamaKhemikhali

- Umatshini wokuzalisa umphanda omkhulu weChemical Liquid

- Umatshini wokuzalisa umgqomo omncinci weMichiza

- Umatshini wokuzalisa umgqomo weMichiza eKrwada

- Umatshini wokuzalisa iBhakethi eliNcinci loMchiza oloNgezelelweyo

- Umatshini wokuzalisa umgqomo omkhulu weChemical Additive

- Umatshini wokuzalisa ulwelo lweeMpahla ezinobungozi

- Umatshini omtsha wokuzalisa ulwelo lwaMandla

- Umatshini wokuzalisa ulwelo lwebhetri yeLithium

- Umbhobho omkhulu wokuzalisa ulwelo lomatshini

- Umatshini wokuzalisa uLwelo lwe-Pharmaceutical

- Umatshini wokuzalisa ulwelo lweResin

- Ipeyinti kunye noMashini wokuTyala wokuZalisa

- Umatshini wokuzalisa imichiza

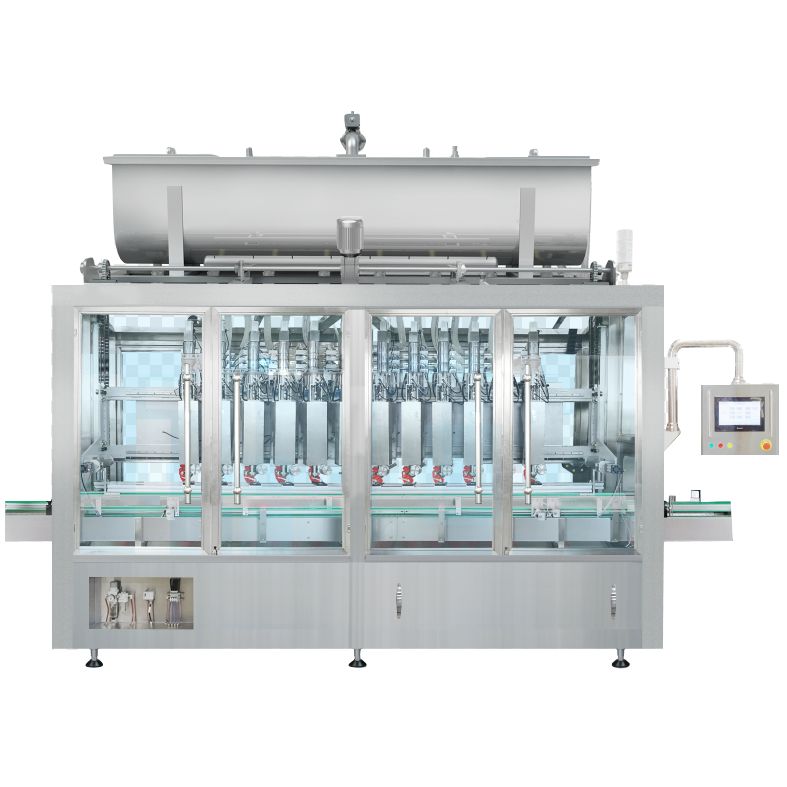

I-20L ye-Barrel Semi-Automatic Chemical Raw Material Filling Machine

Emva kokuba i-barrel engenanto ihanjiswe endaweni, ukuzaliswa kwesantya esikhulu sokuhamba kuqala. Xa umthamo wokugcwalisa ufikelela kumthamo ojoliswe kuwo wokuzaliswa kwe-coarse, isantya esikhulu sokuhamba sivaliwe, kwaye ukuzaliswa kwesantya esincinci siqala. Emva kokufikelela kwixabiso elijoliswe kuyo lokuzaliswa kakuhle, umzimba we-valve uvaliwe ngexesha. Ingumatshini wokupakisha osetyenziswa ngokuqhelekileyo kwizinto ezisetyenziswa ngamachiza ekrwada.

Thumela uMbuzo

Inkqubo yokuhamba:

Emva kokuba i-barrel engenanto ihanjiswe endaweni, ukuzaliswa kwesantya esikhulu sokuhamba kuqala. Xa umthamo wokugcwalisa ufikelela kumthamo ojoliswe kuwo wokuzaliswa kwe-coarse, isantya esikhulu sokuhamba sivaliwe, kwaye ukuzaliswa kwesantya esincinci siqala. Emva kokufikelela kwixabiso elijoliswe kuyo lokuzaliswa kakuhle, umzimba we-valve uvaliwe ngexesha. Ingumatshini wokupakisha osetyenziswa ngokuqhelekileyo kwizinto ezisetyenziswa ngamachiza ekrwada.

Inxalenye yokucoca i-valve yokuzalisa kunye nombhobho wokuzalisa ingachithwa kwaye ihlambuluke, into elula kwaye elula.

IiParameters ezingundoqo zobuGcisa:

|

Inkcazo yomsebenzi |

ipleyiti yokuthontsiza entloko yompu; Umphantsi womatshini wokuzalisa unikezelwa nge-tray ye-liquid ukukhusela ukuphuphuma; |

|

Umthamo wemveliso |

malunga ne-200-400 imigqomo / iyure (20L imitha; Ngokutsho kwe-viscosity yezinto zomthengi kunye nezinto ezingenayo); |

|

Impazamo yokuzalisa |

≤±0.1%F.S; |

|

Ixabiso lesalathisi |

5g; |

|

Izinto eziphambili |

carbon steel spray iplastiki; |

|

Umgangatho wojongano lwezinto |

umthengi unikiwe; |

|

Umthombo womoya ofunekayo |

0.6 MPa; |

|

Uluhlu lobushushu bendawo yokusebenza |

-10℃ ~ +40℃; |

|

Indawo ekusetyenzwa kuyo ukufuma |

< 95% RH (akukho condensation); |